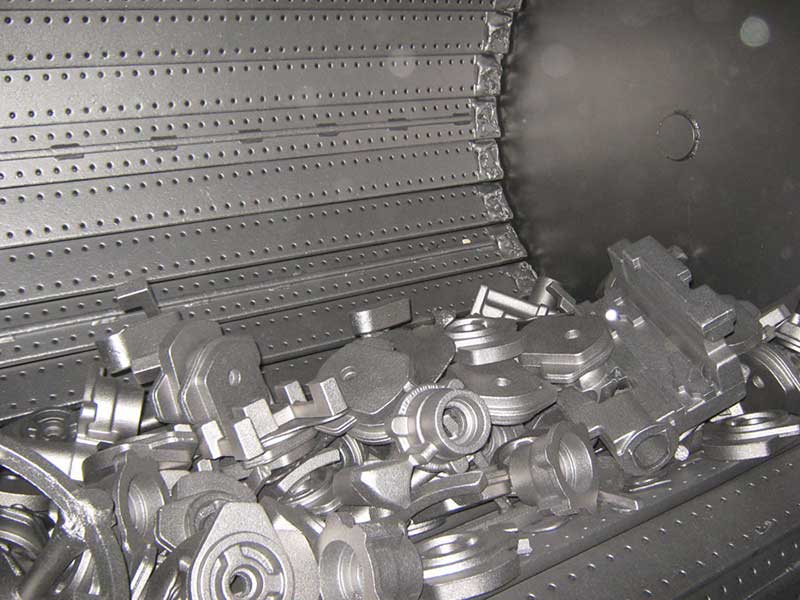

Drum washers are efficient and versatile equipment used in the metalworking industry for batch washing of small and medium-sized parts. These machines are ideal for removing oil, dirt, chips and other debris from the surfaces of parts after processes such as casting, forging, machining, etc.

Working Principle:

Drum washers work on the principle of rotating parts in a cleaning solution placed in a drum that rotates around a horizontal or slightly inclined axis. The rotational motion of the drum ensures that the parts are constantly in contact with the cleaning solution, resulting in a homogeneous cleaning process. The cleaning solution dissolves and removes dirt from the surface of the parts.

Key Components:

- Drum: It is the main component in which the parts are placed and provides the rotational movement. It is usually made of stainless steel or other durable materials.

- Cleaning Solution Tank: It is the tank where the cleaning solution is stored and heated.

- Pumps and Piping: It is the system that provides the return of the cleaning solution from the tank to the drum and back.

- Heating System: It is the system that ensures that the cleaning solution is kept at the desired temperature.

- Filtration System: It is the system that ensures that the dirt and residues in the cleaning solution are filtered and cleaned.

- Drying System (Optional): It is the system that allows the parts to be dried after the washing process.

- Control Panel: It is an electronic or mechanical control unit that allows the adjustment and monitoring of the operating parameters (rotation speed, temperature, time, etc.) of the machine.

Uses:

- Automotive Industry: Cleaning of small automotive parts (screw parts, small cast parts, etc.).

- Metalworking Workshops: Cleaning and surface preparation of small metal parts (nuts, bolts, small cast parts, etc.).

- Heat Treatment Industry: Removal of oil and oxide layer of small parts that have been heat treated.

- Foundry Industry: Deburring small casting parts.

- Aerospace Industry: Cleaning of small aerospace parts.

- Electronics Industry: Cleaning of small electronic parts.

Advantages:

- High Efficiency: Batch washing of small and medium-sized parts saves time and labor.

- Homogeneous Cleaning: The rotating motion of the drum ensures that all sides of the parts are cleaned evenly.

- Versatility: It can meet various cleaning requirements by using different cleaning solutions and working parameters.

- Automation: It can be easily integrated with automatic loading and unloading systems and can be easily incorporated into production processes.

- Cost-Effectiveness: The batch washing process reduces the cost per piece.

Disadvantages:

- Not Suitable for Large Parts: Due to the dimensions of the drum, it is not possible to wash large parts.

- Requires Caution for Sensitive Parts: There is a risk of damage to sensitive parts due to parts hitting each other.

- Cleaning Solution Tracking: The cleaning solution needs to be checked and changed regularly.

- Maintenance Requirement: The drum and other mechanical parts need to be maintained regularly.

Drum washers offer an efficient and reliable solution for cleaning small and medium-sized parts in the metalworking industry. When used correctly, it can significantly improve manufacturing processes.