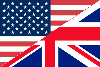

Working Principle

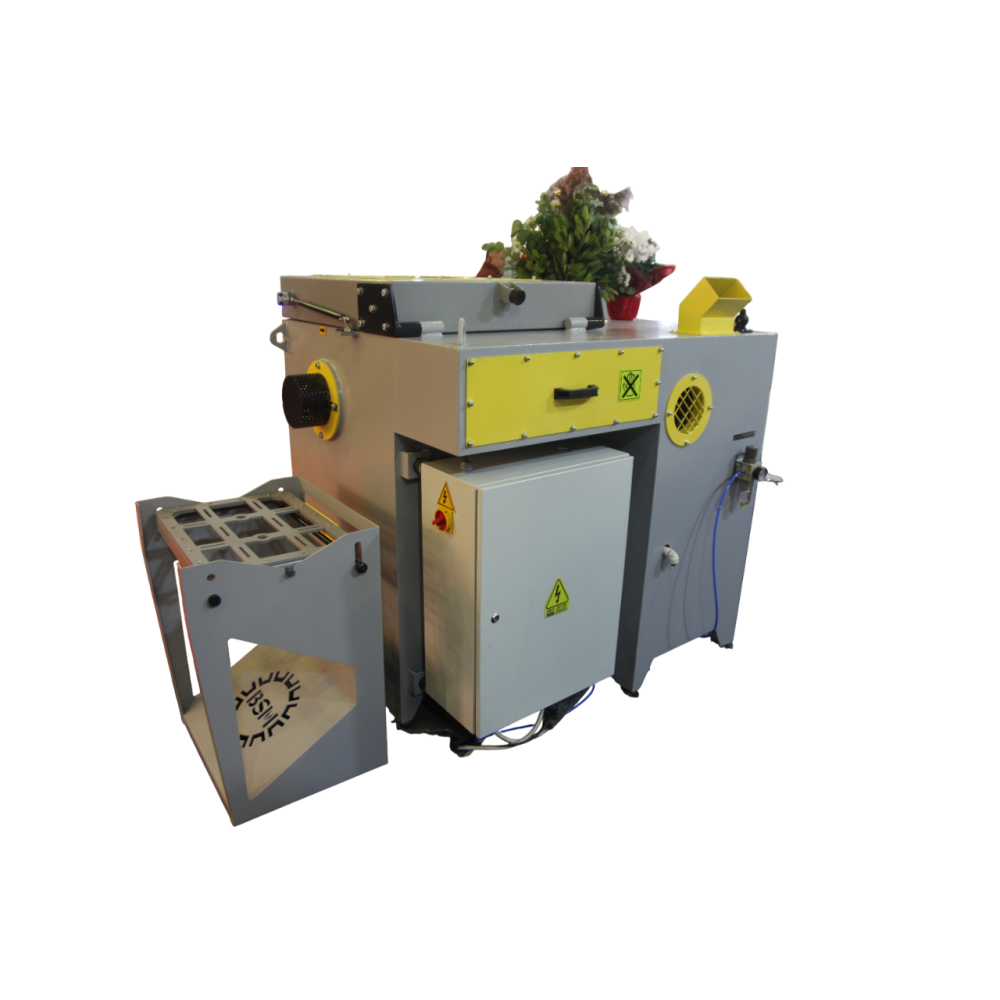

The Cage-Type Washing Machine is an automatic system developed for cleaning, degreasing, and rinsing small and medium-sized parts either individually or in bulk. The parts are continuously moved through a rotating mechanism, tumbling around their axis within the cage to be cleaned. During this process, pressurized water and chemical solutions sprayed from nozzles wash the parts. As the parts dip in and out of the bath, the cleaning liquid reaches all points of the parts, including those with complex geometries, ensuring maximum cleanliness.

Filtration and Heating System

During the washing process, components like water and cutting oil are filtered through a filtration module. The liquids are heated by the integrated heating resistors, which enhances cleaning efficiency.

Drying Stage

After the washing process, a hot air blowing fan is activated. This fan quickly removes the water from the washed parts, ensuring they dry quickly. No water residue remains on the parts.

Cleaning Stages

🔹 Degreasing: Oil and dirt on the parts are removed using effective solvents. 🔹 Rinsing: Chemical residues are removed using water spraying. 🔹 Drying: Fast and efficient drying with a hot air blowing fan.

Advantages

✔ Automatic and continuous cleaning with minimal labor requirements

✔ Homogeneous and deep cleaning for maximum surface cleanliness, even on delicate surfaces

✔ Filtration and recycling systems for water and chemical savings

✔ More effective cleaning with heated liquids due to the heating system

✔ Quick and efficient drying with hot air blowing fan

✔ Durable and long-lasting design suitable for heavy industrial conditions

Applications

🔸 Automotive Industry – Engine parts, turned and milled parts, gears

🔸 Metalworking Industry – Surface cleaning after cutting, drilling, and welding

🔸 Foundries – Removal of sand and casting residues

The Cage-Type Washing Machine is an innovative solution that enhances speed, efficiency, and quality in cleaning processes. Contact us for more information!